Results

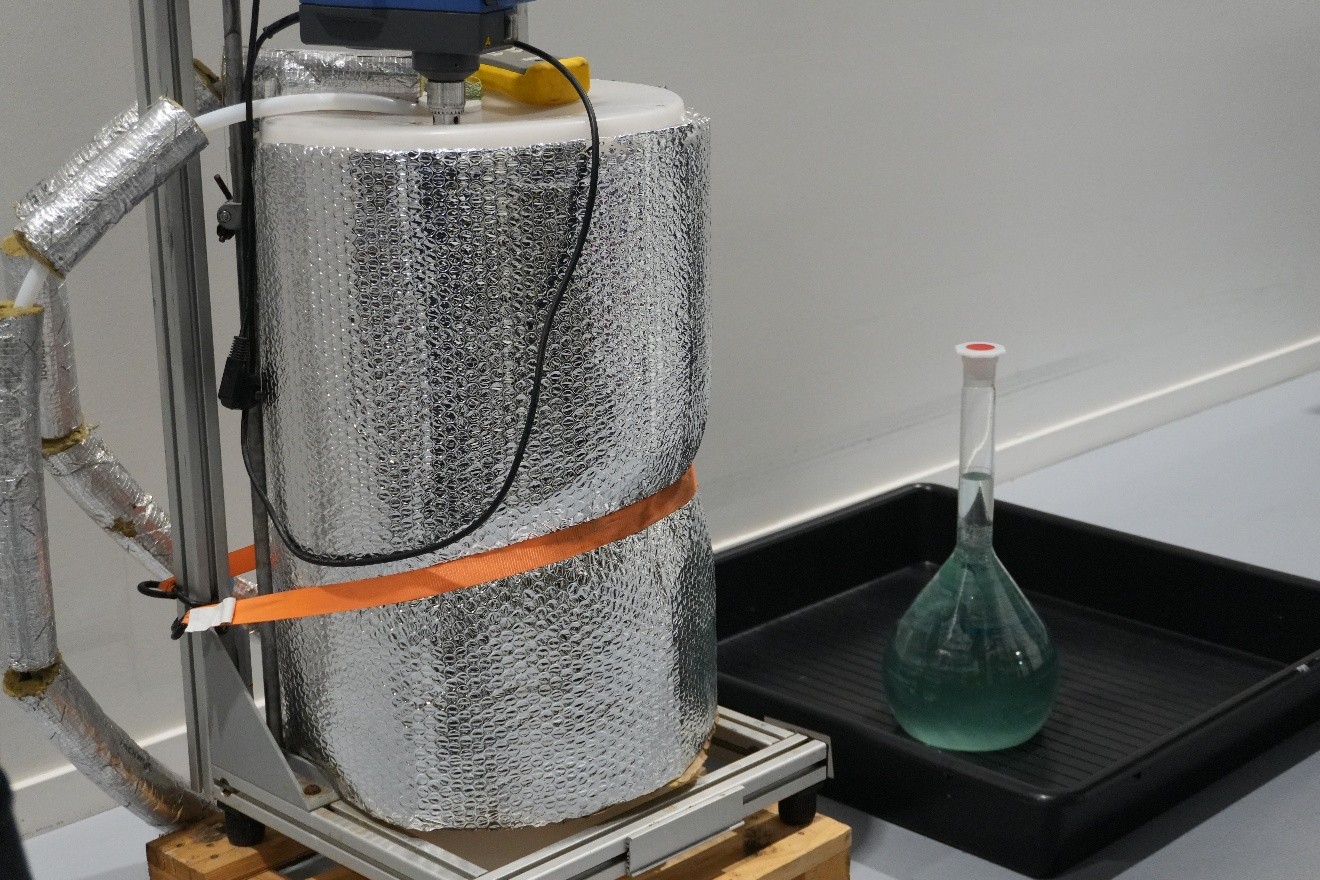

After three and a half years of research, the EU research project RELiEF has successfully concluded and presents its results and solutions for lithium and battery recycling in Europe and beyond. The consortium of 12 academic and industrial partners jointly worked on developing a process to produce battery materials from secondary and low-grade lithium sources as well as safe and efficient pre-processing unit operations for solid input materials.

Find out what has been accomplished!